Bartender Kit • 3x3 m • customised

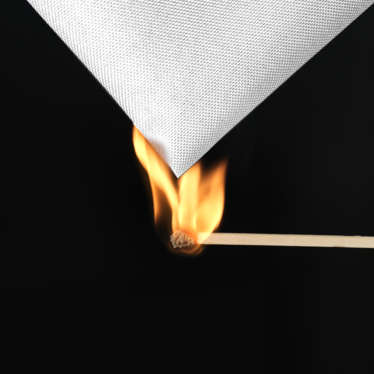

Oxford 500D fire retardant

Our Bartender Kit is the ultimate solution for serving beer, beverages, and cocktails at any event, whether indoor or outdoor.

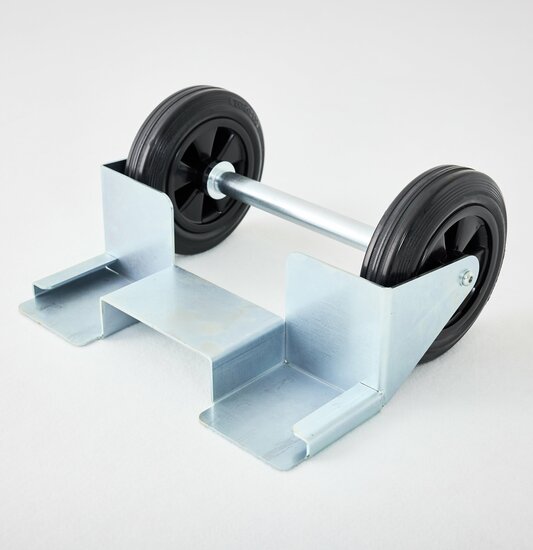

It provides the perfect workspace for drink services, offering easy set-up and transport without compromising on stability and safety. Designed to withstand UV rays and weather conditions, it is durable, fire-retardant, and certified for food use. Enhance your Bartender Kit's appearance by working with our expert design team to create a striking and unforgettable stand that captures the attention of every visitor.

Start with this standard Bartender Kit configuration and personalise it with new sizes, accessories, or side panels in the configurator to perfectly match your needs.

| Included in the delivery: |

|

| Features: |

|

| Space for: |

|

| Materials: |

|

| Profile: |

|

| Set-up: |

|